JICS CE Test okay helmet mould

Motorcycle integrated helmet with wind shield mould

Outdoor power supply large capacity mobile power supply power accumulator 2

Outdoor power supply large capacity mobile power supply power accumulator 3

Outdoor power supply large capacity mobile power supply power accumulator handle

Outdoor power supply large capacity mobile power supply power accumulator bottom case

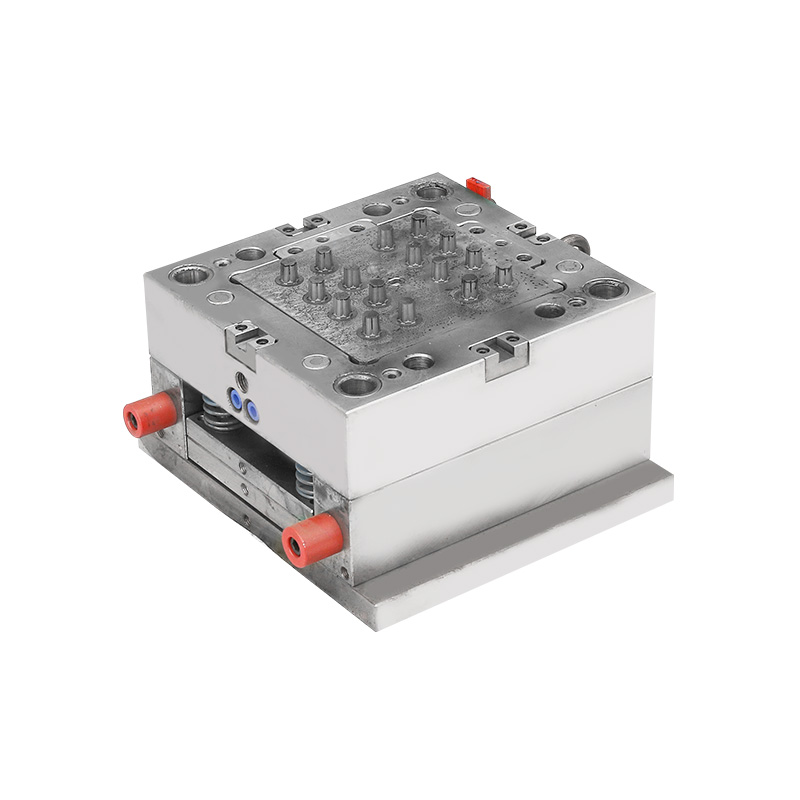

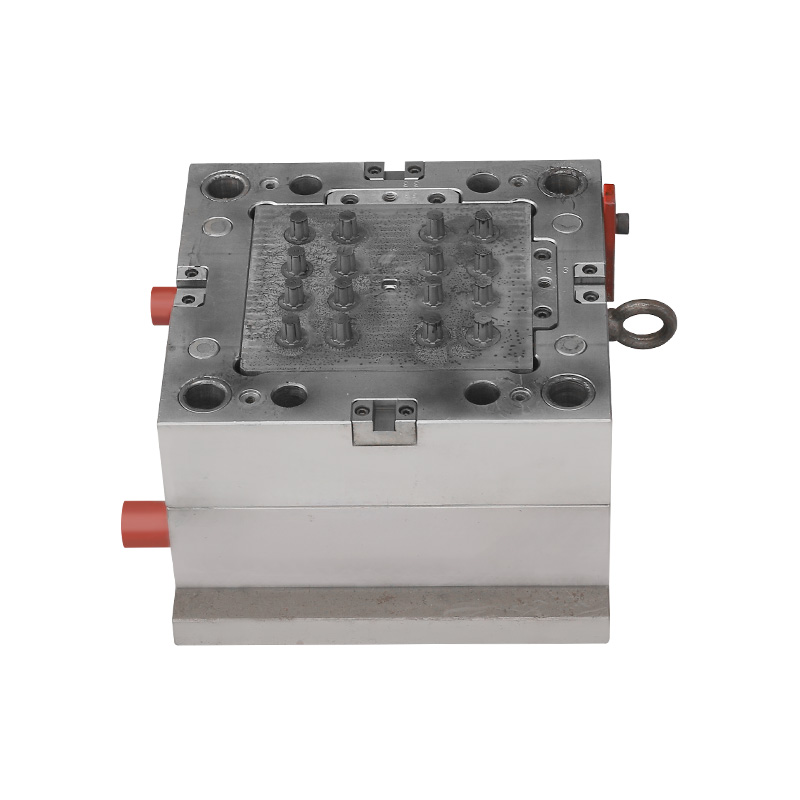

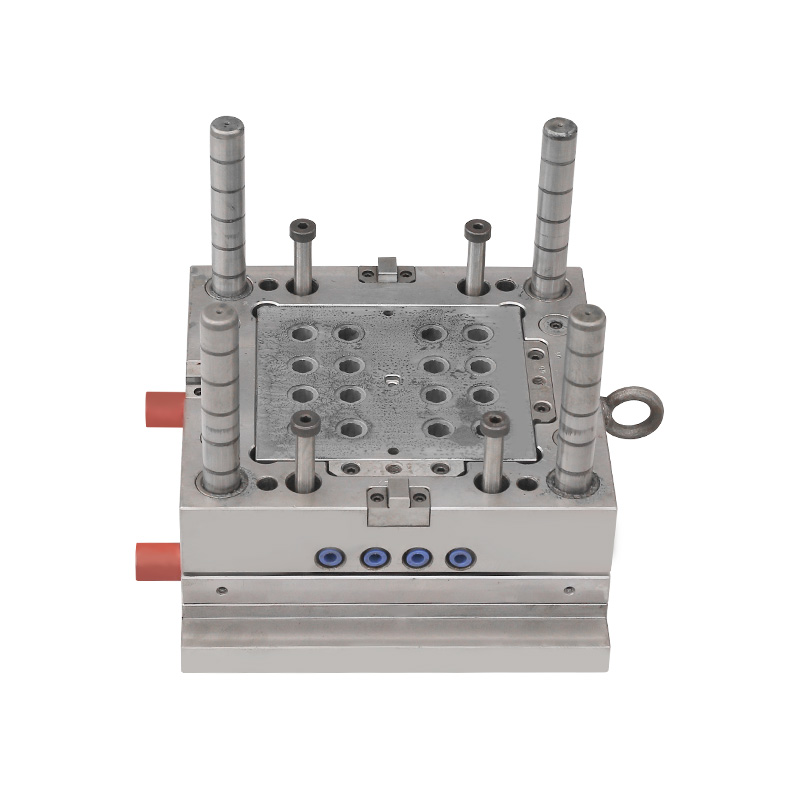

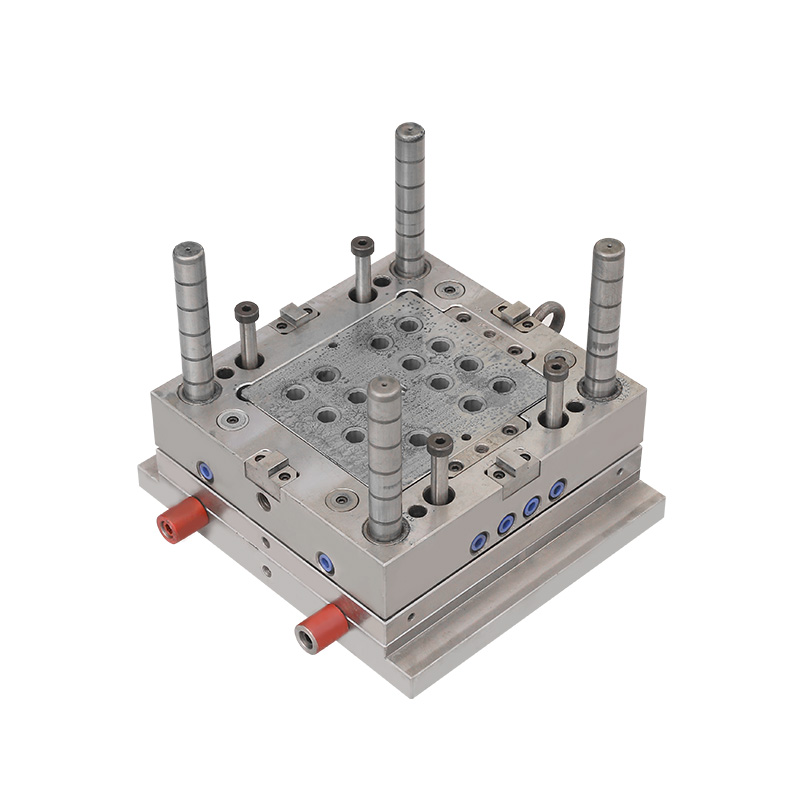

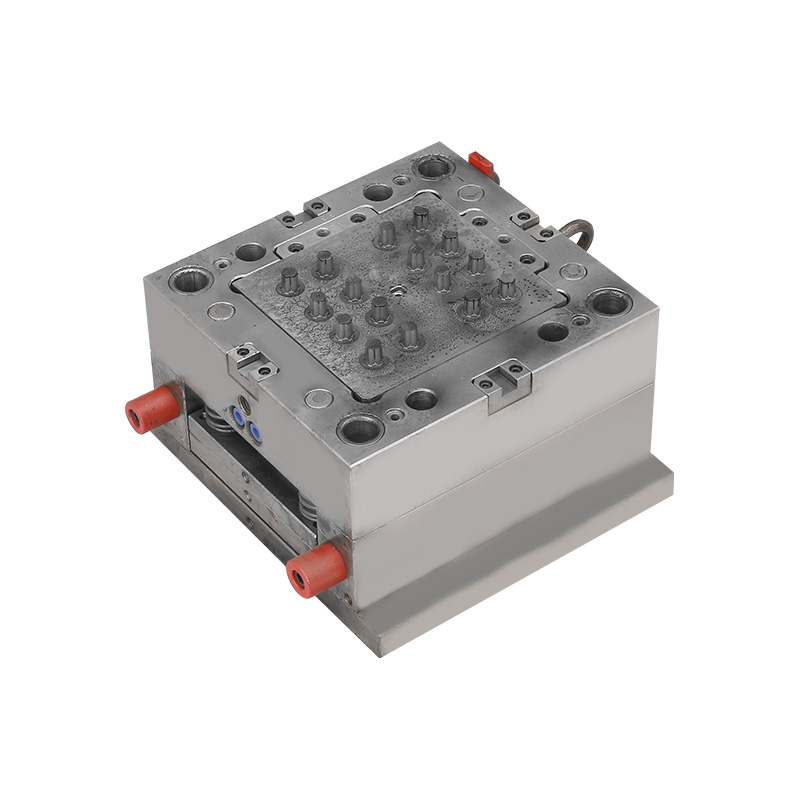

CPVC fitting mould male adaptor with brass insert

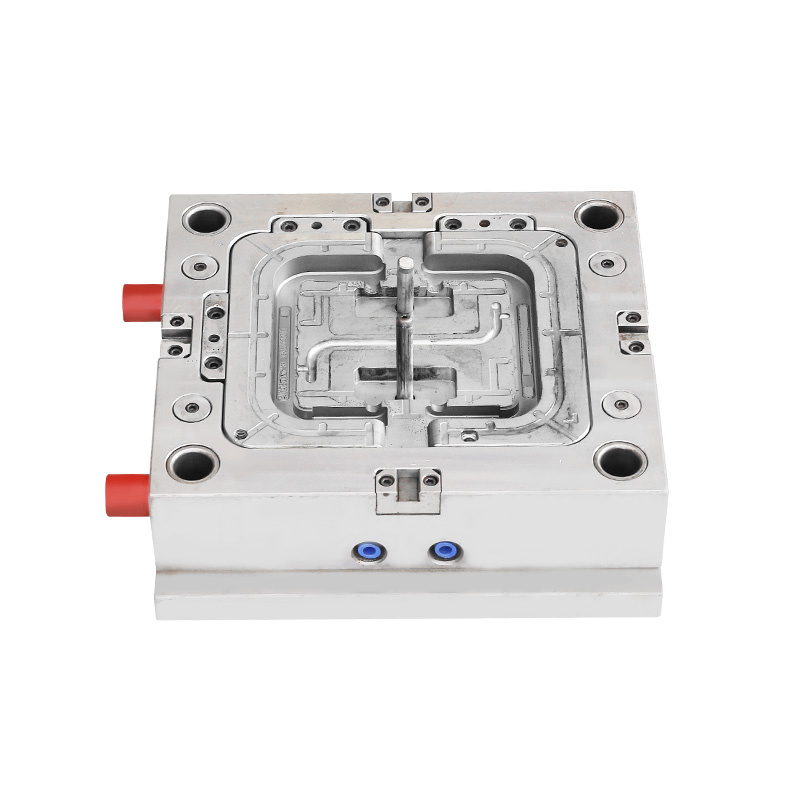

Cuotomized PVC pipe fitting mould

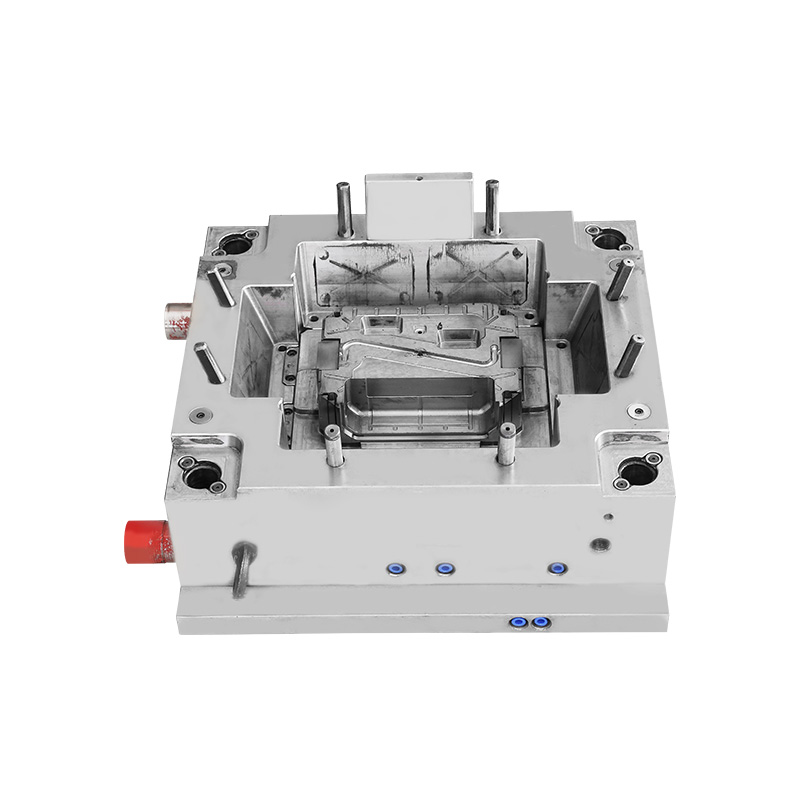

PP fitting mould collapsible Elbow 90 degree

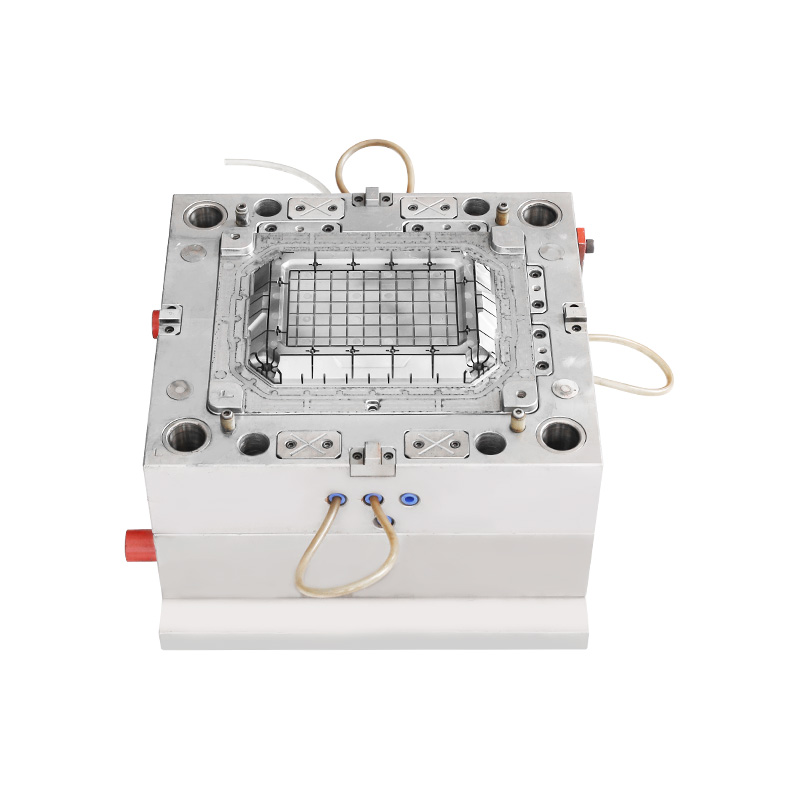

PVC collapsible tee pipe fitting mould